Proactive Risk Reduction in Facilities Management: The Power of "FMEA"

Share

In the dynamic world of Facilities Management (FM), minimizing risks and avoiding equipment failure are top priorities. While Root Cause Analysis (RCA) helps us understand why failures happened, another powerful tool—Failure Modes and Effects Analysis (FMEA)—helps us anticipate how things might fail in the first place.

What is FMEA?

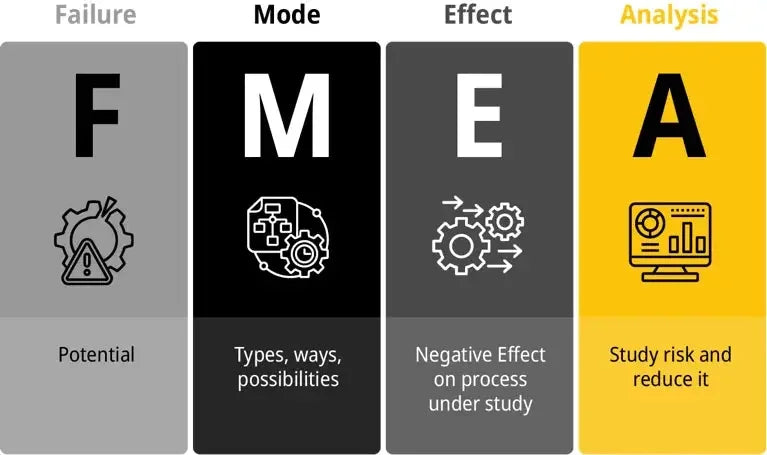

Failure Modes and Effects Analysis (FMEA) is a systematic, proactive method for identifying potential failure modes in systems, processes, or equipment, evaluating their consequences, and prioritizing mitigation strategies before the failure occurs.

Originally developed by NASA and the U.S. military, FMEA is now widely adopted across industries including manufacturing, healthcare, and FM.

Why Use FMEA in Facilities Management?

FM professionals are responsible for maintaining safe, efficient, and cost-effective environments. FMEA helps by:

Predicting potential points of failure in critical building systems (e.g., HVAC, elevators, fire safety)

Reducing unplanned downtime

Enhancing preventive maintenance plans

Improving compliance with ISO standards like ISO 41001

FMEA Process in FM (Step-by-Step)

Identify the system or asset

Choose a key facility system or asset (e.g., a chilled water plant).

List potential failure modes

What could go wrong? (e.g., pump failure, control sensor drift, valve blockage)

Assess effects of each failure

What is the consequence of each failure on operations, safety, comfort, or cost?

Assign Severity (S), Occurrence (O), and Detection (D) ratings

Rate each failure mode on:

Severity: Impact on the system if the failure occurs

Occurrence: Likelihood of the failure happening

Detection: Likelihood the issue will be detected in time

Calculate Risk Priority Number (RPN)RPN = S × O × D

Higher RPN = higher priority for corrective action

Plan corrective actions

Modify maintenance schedules, install monitoring devices, or redesign systems

Review and repeat

FMEA should be a living document, updated with each failure, audit, or system change.

Real-World FM Application Example

Asset: Air Handling Unit (AHU)

Failure Mode: Motor overheating

Effects: HVAC downtime, occupant discomfort, increased energy consumption

Mitigation: Add motor temperature sensors, increase PM frequency, use predictive analytics

Benefits of FMEA in FM

Reduces emergency repairs

Supports ISO-compliant risk assessments

Justifies CAPEX investments with risk data

Drives smarter, proactive O&M strategies

FMEA vs RCA in FM

| Aspect | FMEA | RCA |

|---|---|---|

| Timing | Before failure (preventive) | After failure (reactive) |

| Goal | Risk mitigation | Root cause identification |

| Usage Frequency | Regular part of O&M planning | Event-driven (after incident) |

Conclusion

FMEA is an essential addition to the modern FM toolbox. When combined with techniques like RCA, it creates a powerful framework for anticipating risks, minimizing downtime, and extending asset life cycles.

Implementing FMEA into your FM strategy signals a shift from reactive maintenance to strategic resilience and operational excellence.